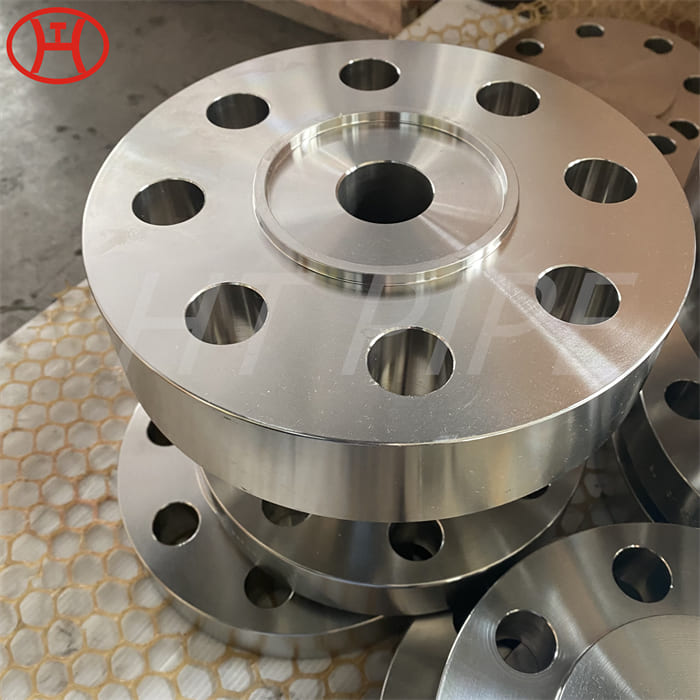

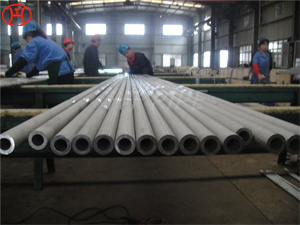

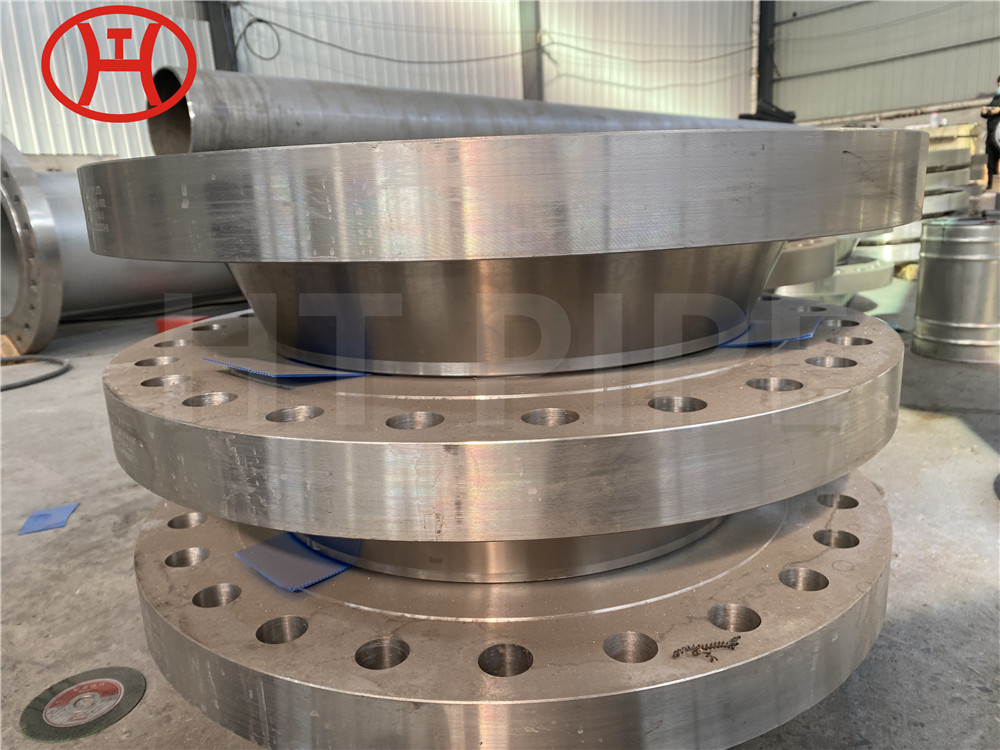

Monel 400 bw pipe fittings 2.4360 elbows and tees

Monel 400 Tee is a nickel-copper alloy resistant to seawater and steam at high temperatures, as well as salts and corrosive solutions. Monel 400 Pipe Elbows operate over a wide temperature range and are available in a variety of styles for a variety of products.

Monel 400 is a high performance, high strength nickel and copper alloy (with trace amounts of iron, manganese, carbon and silicon). It has excellent acid and alkali resistance, good ductility and good thermal conductivity, and can only be hardened by cold working. Monel 400 is suitable for applications with operating temperatures ranging from subzero to 1,000°F (538°C).

Copper alloys are generally very resilient to salt water, making them suitable for marine engineering applications. Alloy 400 fittings will also exhibit good resistance to corrosive solutions and salt water, although the alloy has a higher nickel content (about 67% of the total alloy weight). Caustic solutions including potassium hydroxide or sodium hydroxide solutions will not affect mild concentrations of alloys at ambient temperature settings. However, this is not the case if the temperature of the solution or concentration increases. Ordinary steel corrodes rapidly.

Alloy 400 is a nickel-copper alloy (approximately 67% Ni – 23% Cu) resistant to seawater and steam at high temperatures, as well as salt and caustic solutions. Monel 400 fittings are also extremely resistant to stress corrosion cracking in most fresh waters. High temperatures (up to 1000°F) have no effect on this alloy, and it also has excellent mechanical properties at sub-zero temperatures.

These Monel 400 butt welded fittings (high corrosion alloy material) are used in oil and gas, heat exchangers, aerospace, pharmaceutical, defense, electrical and electronic parts, chemical transport barrels and other industries.