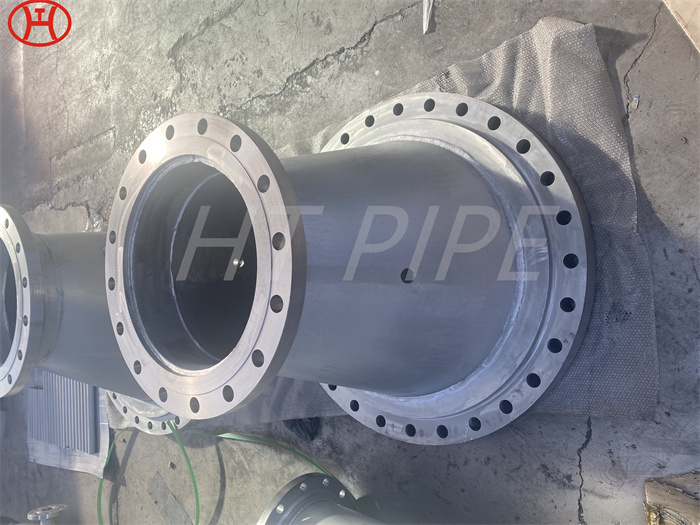

s32750 duplex steel pipe 1.4410 pipe

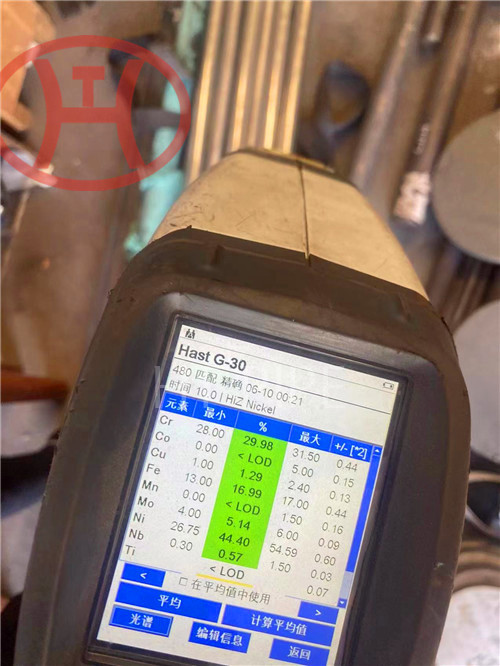

S31803 stainless steel is a nitrogen alloy duplex stainless steel containing 22% chromium, 3% molybdenum, and 5-6% nickel. In addition to high strength and excellent impact toughness, it also has high resistance to general corrosion, localized corrosion and stress. Corrosive properties.

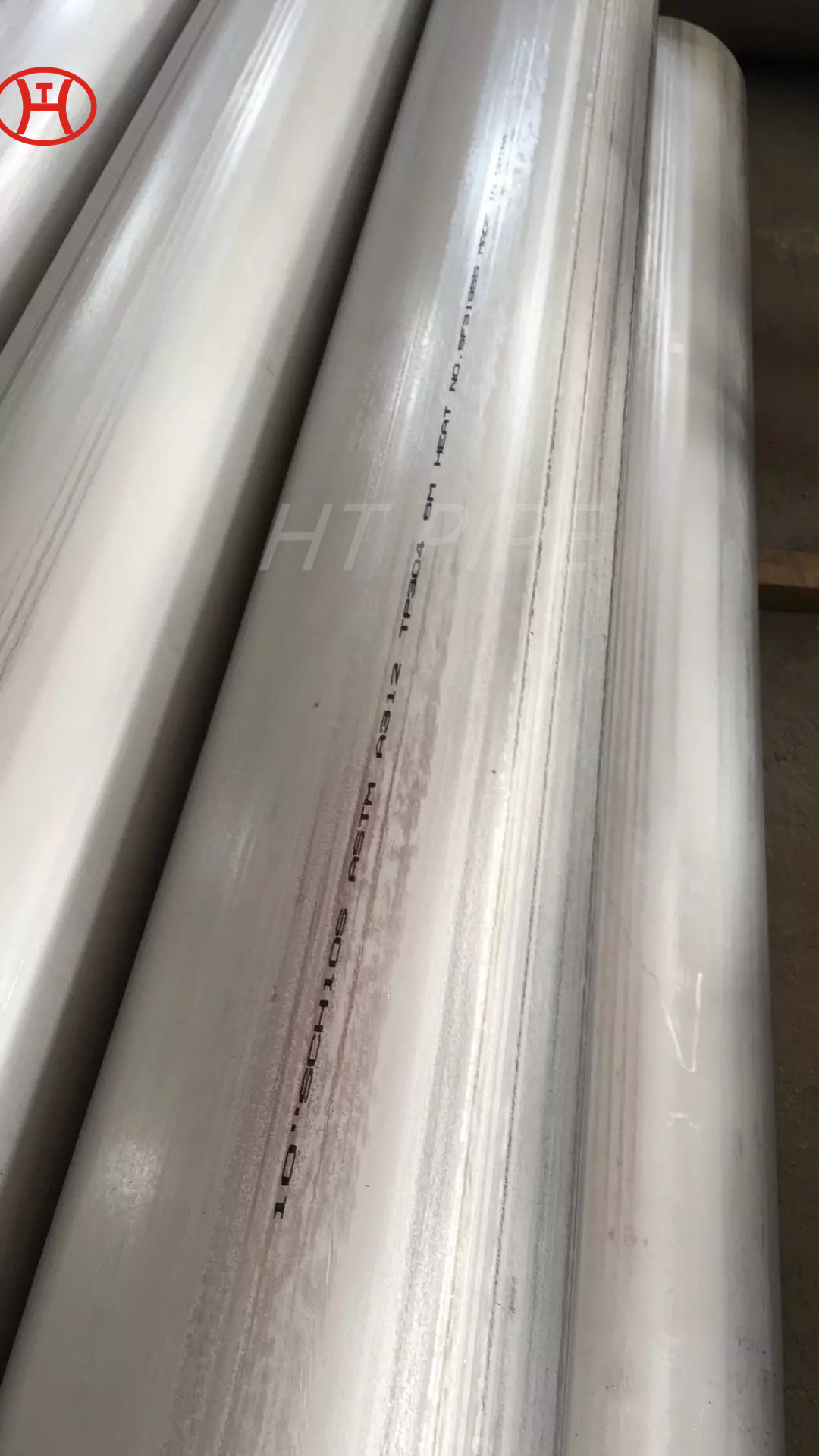

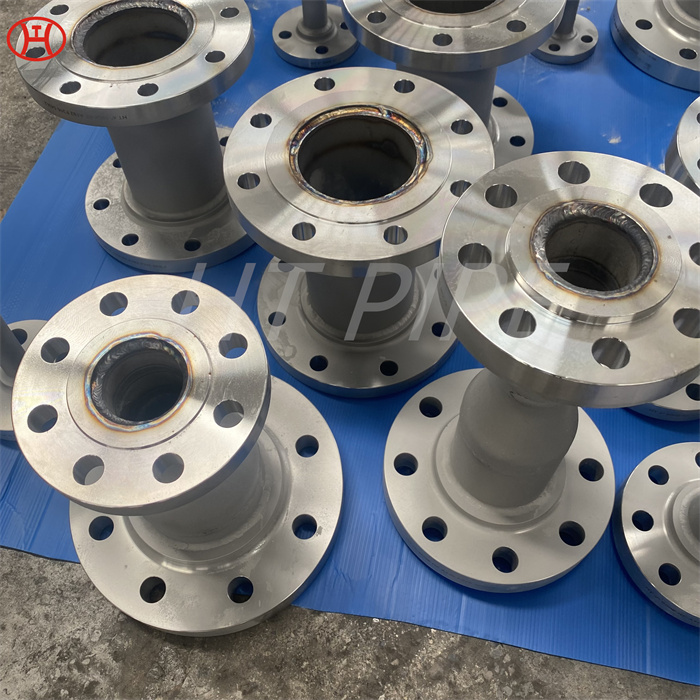

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

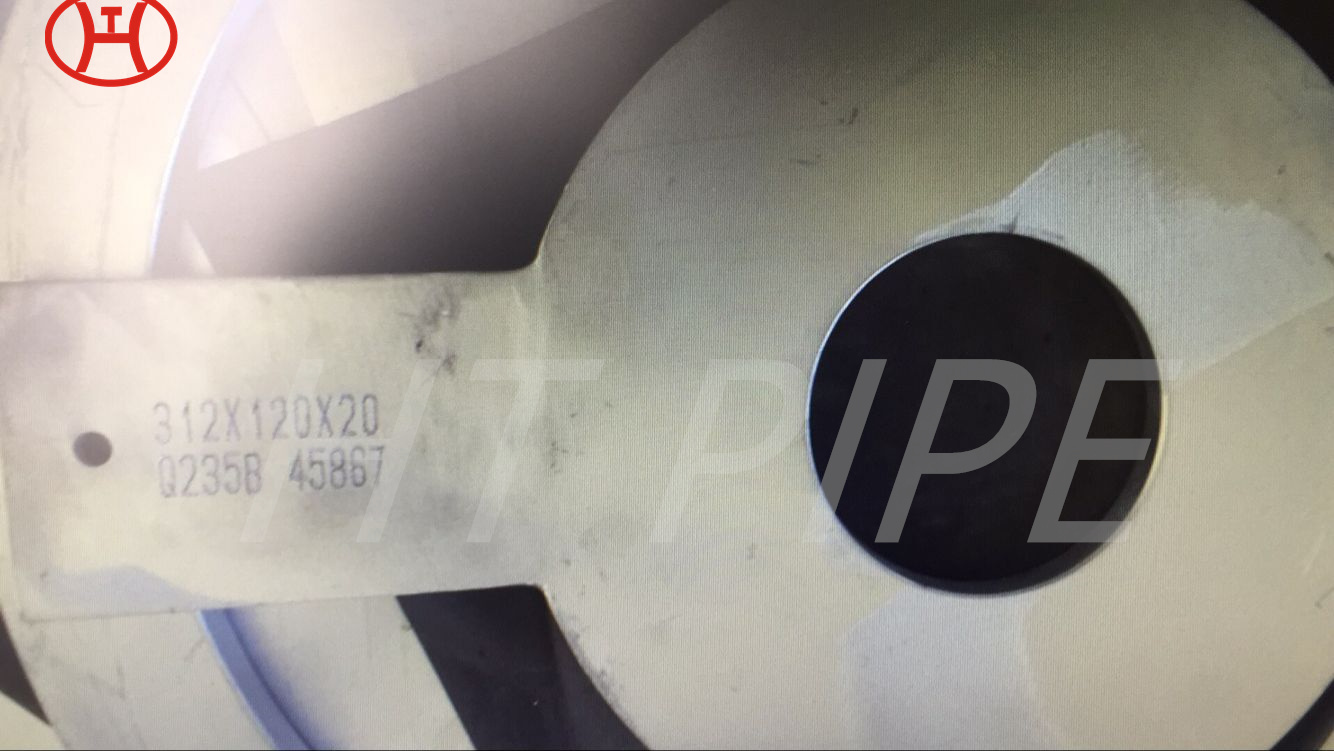

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.61

Alloy 32750 is a super duplex stainless steel supplied in solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of austenitic and ferritic steels. Super Duplex UNS S32750 is the most common Super Duplex grade on the market. UNS S32750 is a duplex stainless steel designed for use in corrosive chlorine-containing environments. It has very good localized corrosion and stress corrosion cracking resistance and high mechanical strength. Widely used in oil and gas, hydropower, pressure vessels, pulp and paper, structural parts and chemical tankers. Duplex stainless steel alloys have ferritic/austenitic properties that give these materials excellent strength and excellent oxidation resistance. While the duplex grade range includes a wide range of specific formulations, duplex S31803 (2205) and super duplex S32750 (2507) stainless steels are the two most common.