A105 forged pipe fittings supplier swage nipple

Carbon steel forged fittings and flanges are prevalent and common used in industries, the representative material grade is ASTM A105 and A350 LF2/LF3.

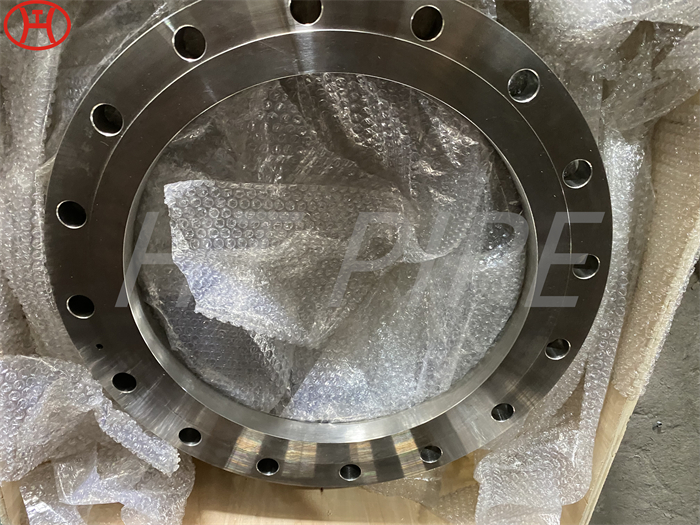

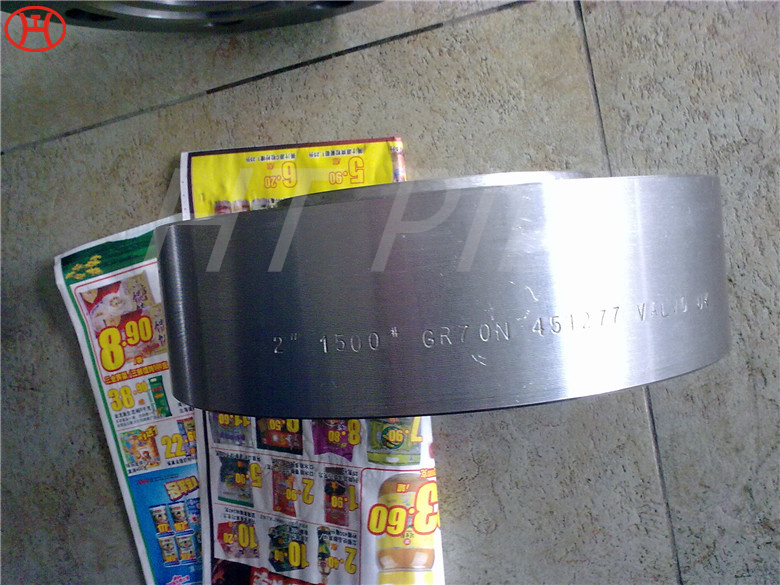

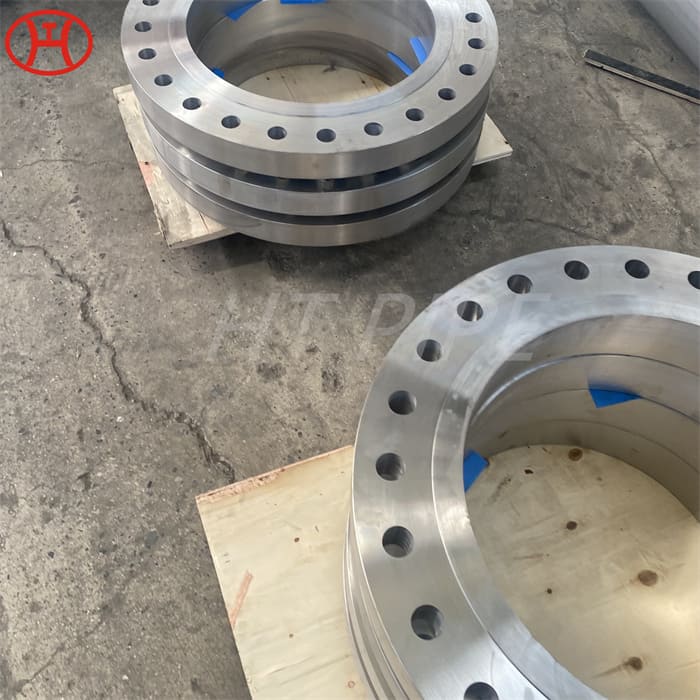

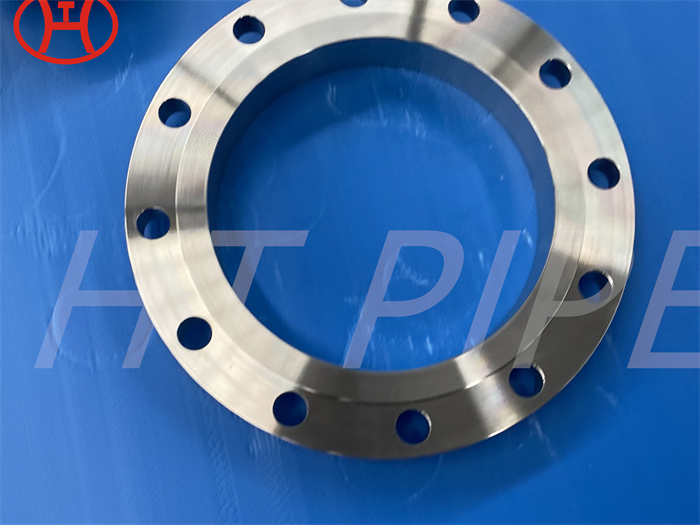

Carbon Steel A105 High Pressure Forged Fittings, Carbon Steel A105 Threaded Fittings, Carbon Steel A105 Socket weld Fittings, Carbon Steel ASTM A105 Threaded Fittings, Carbon Steel A105 Industrial Forged Fittings

ASTM a105 forged fittings is heavier, thicker and are intended for heavy industrial use. It is made up of forged carbon steel. Forging steel process makes the fitting very strong. Carbon steel is heated to molten temperatures and placed in the dies. The heated carbon steel is then machined into the forged steel fittings. carbon steel astm a105 fittings is used for ambient- and higher-temperature service in pressure systems.

ASTM A105 pipe fittings is used for installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. sa 105 fittings comes in a variety of sizes to fit the pipe they will connect. It is useful to combine, divert or reduce the flow of the water supply. We are Manufacturers, Suppliers, and Exporters of carbon steel ASTM A105 Forged Fittings, which are forged, carbon steel piping solutions to be used with pressure systems performing at higher also as ambient temperatures. ASTM A105 Screwed Threaded Pipe Reducer is low Carbon, Manganese, and Silicon added fittings that are usable for non-critical yet pressure applications, like refrigeration fittings, that work at constant temperatures. They provide maximum machinability and weldability as their low carbon reducers.

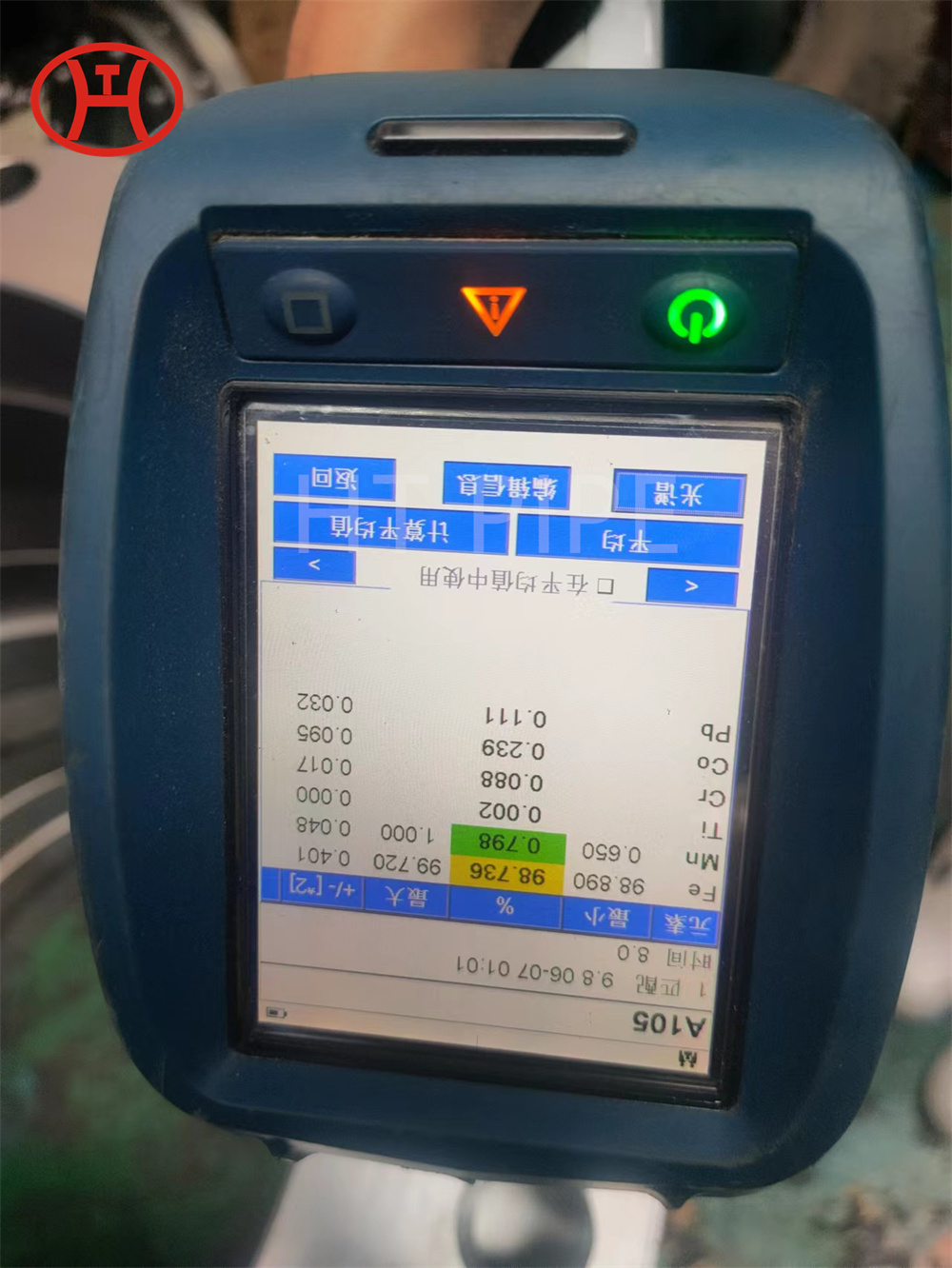

Chemical Structure of ASTM A105 pipe fitting

| C | Mn | P | S | Si |

| .35 max | .60/1.05 | .040 max | .05 max0 | .35 max |

ASTM A105 forged fitting Mechanical Properties

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |