Standard Specification For ASTM A105N Flanges

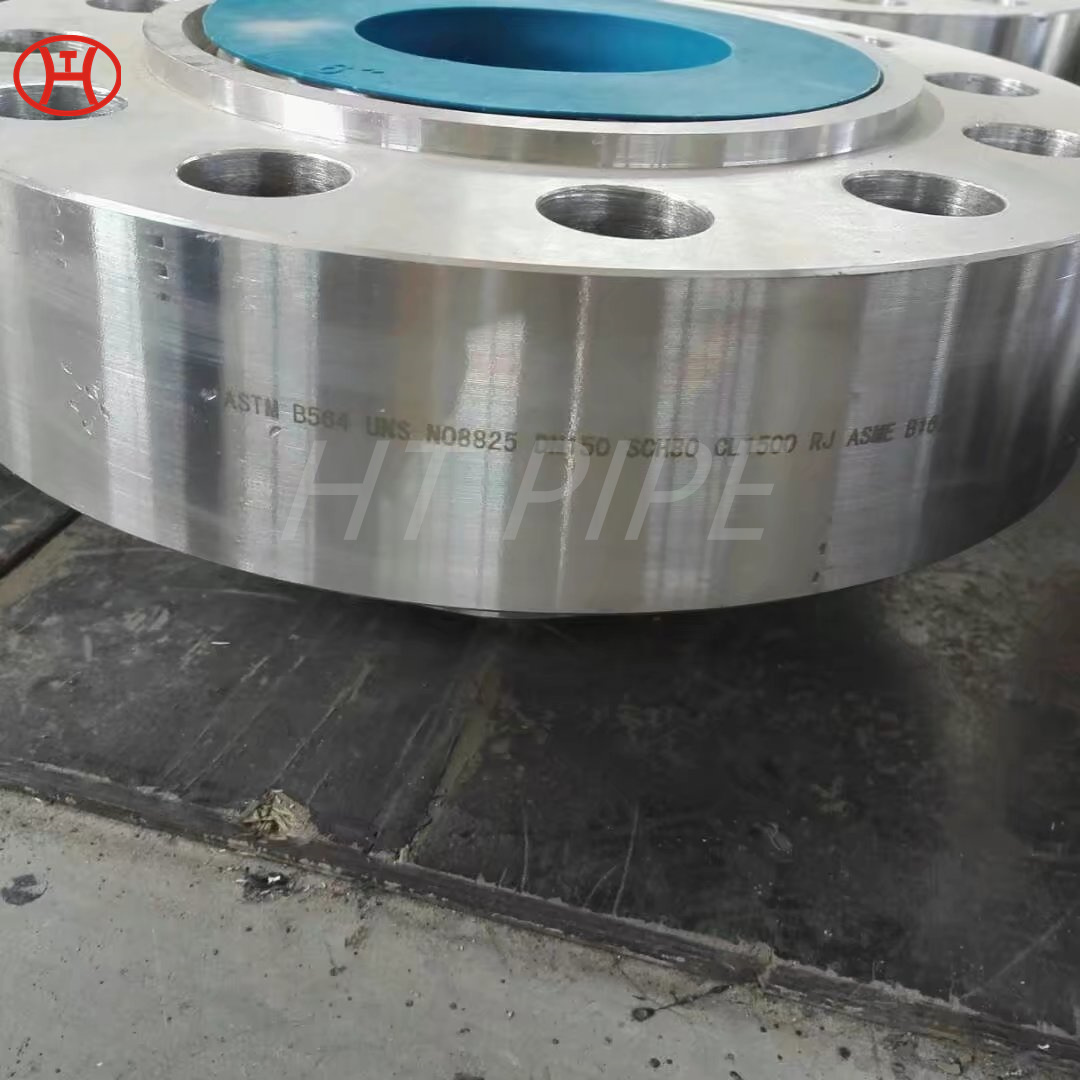

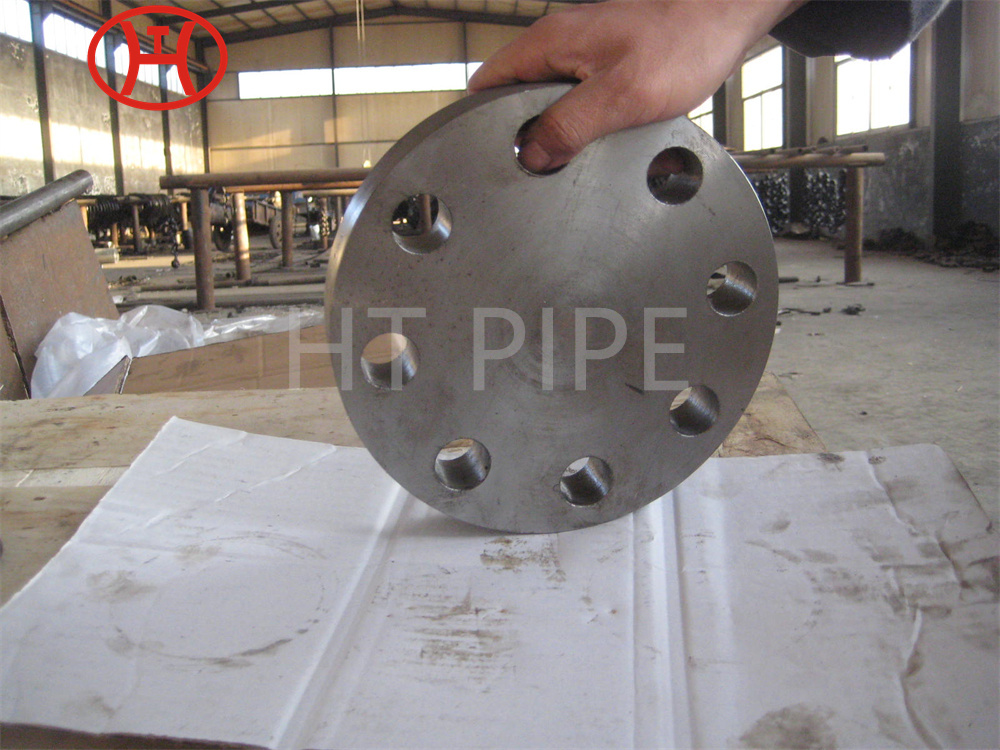

| Specification | ASTM A105N / ASME SA105N |

| Dimensions | ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631–2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, TABLE D, TABLE E, TABLE F, TABLE J etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size | 1/2″ to 48″ |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

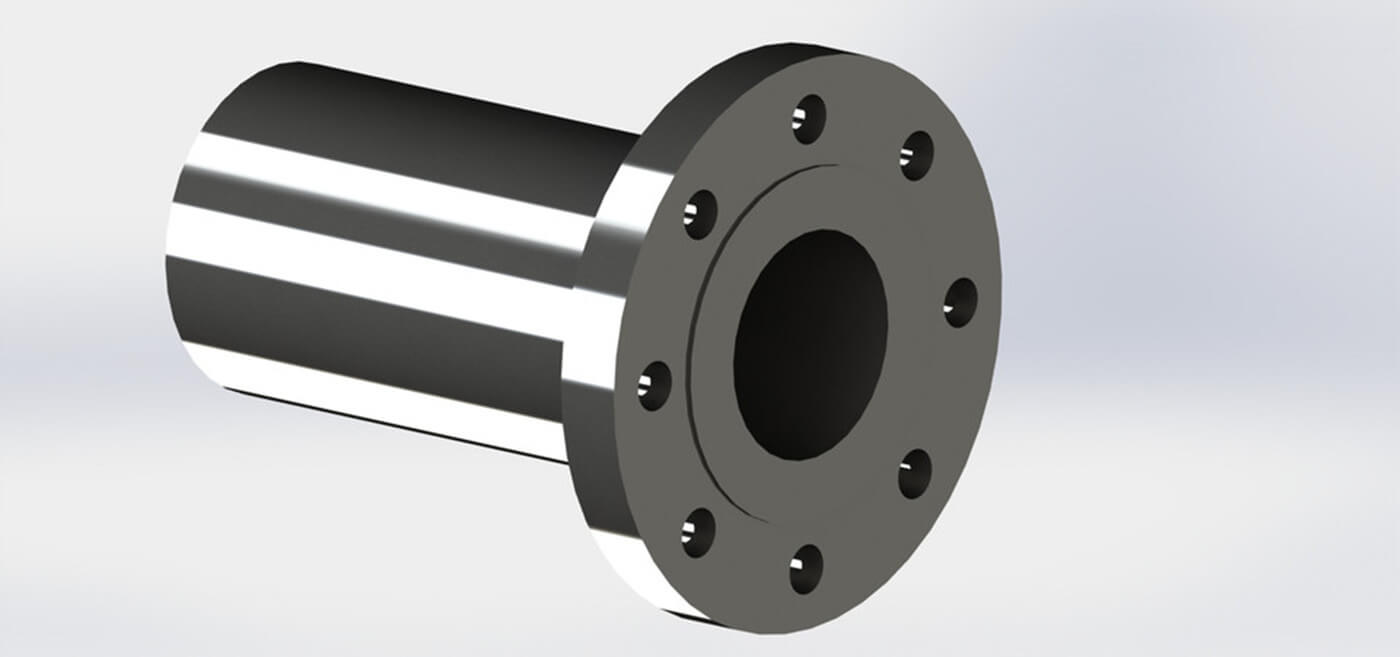

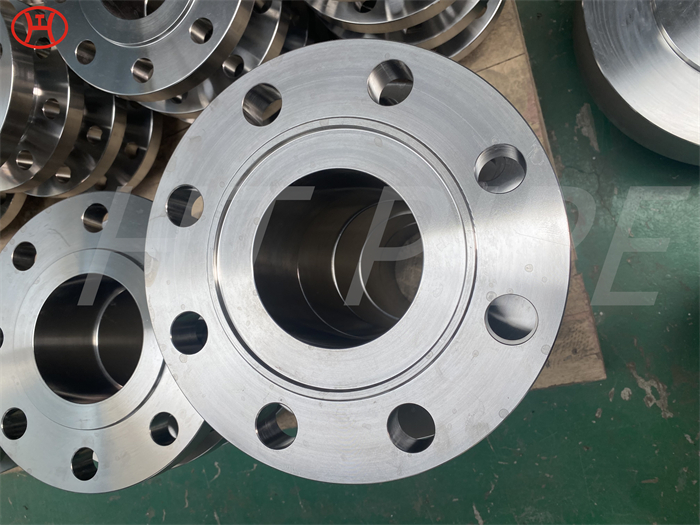

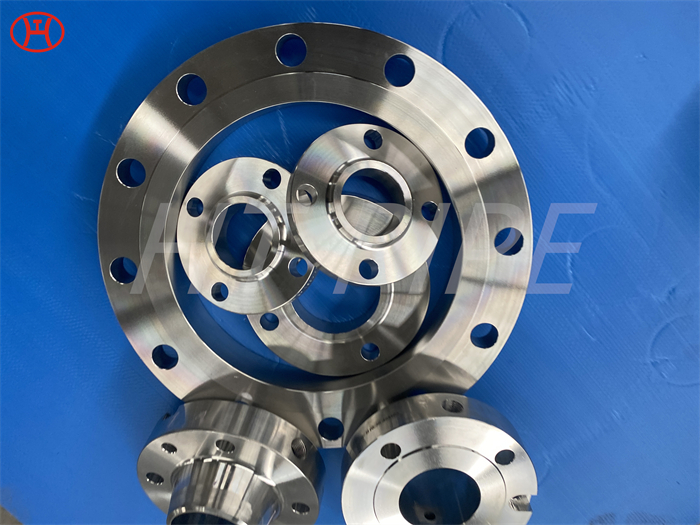

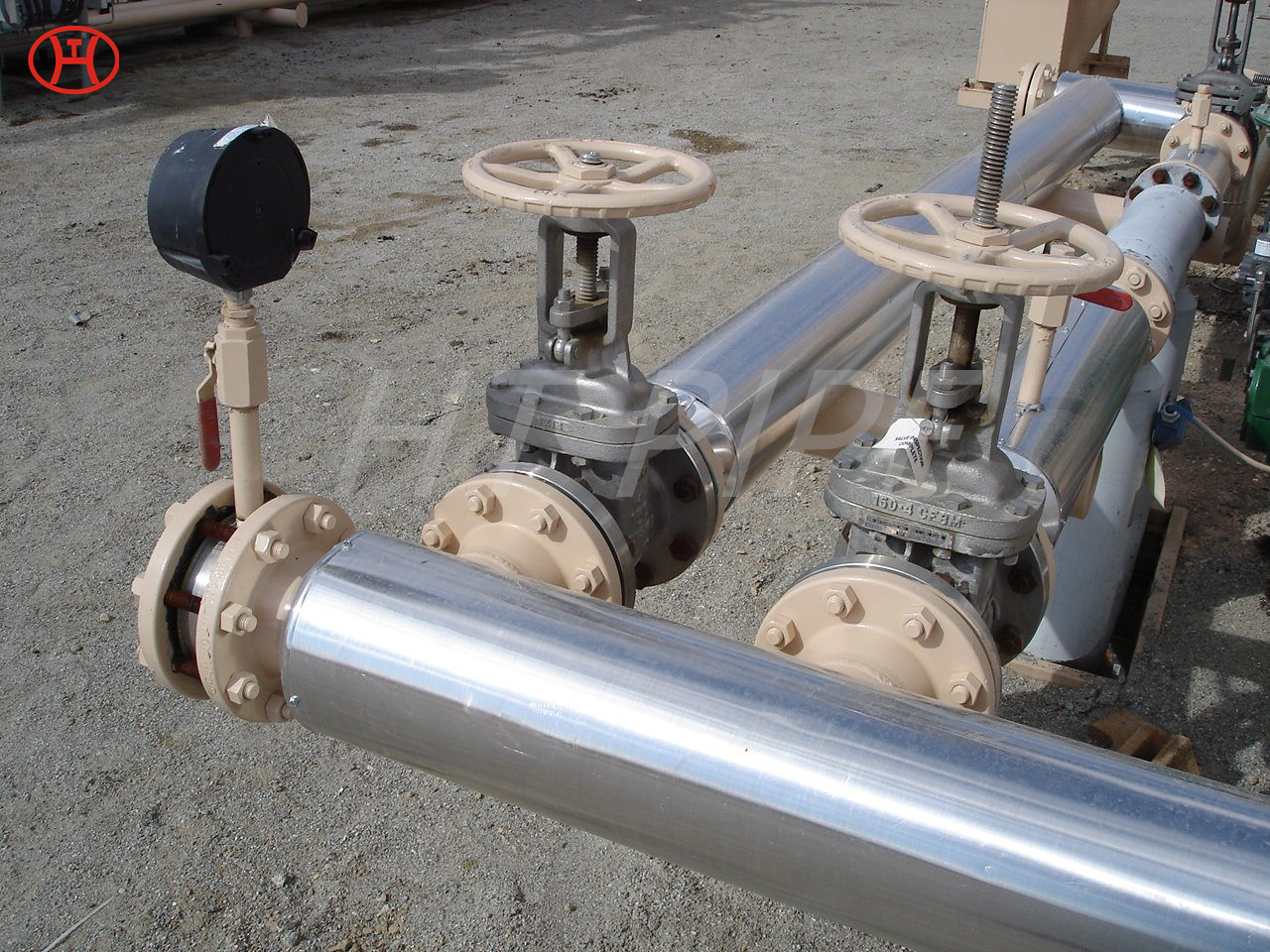

| Types | ASTM A105N Slip On Flange, ASTM A105N Socket Weld Flange, ASTM A105N Threaded / Screwed Flange, ASTM A105N Orifice Flanges, ASTM A105N SORF Flange, ASTM A105N Welding Neck Flange, ASTM A105N Long Welding Neck Flanges, ASTM A105N SWRF Flange, ASTM A105N Custom Flange as per Drawing etc., ASTM A105N Weldoflange, ASTM A105N Expander Flange, ASTM A105N Nipoflange, ASTM A105N Reducing Flange, ASTM A105N Plate Flange, ASTM A105N WNRF Flange, ASTM A105N Blind Flange, ASTM A105N Lap Joint Flange, ASTM A105N Pipe Flange |

| Value Added Services | CNC Machining, Cold and Hot Dip Galvanized, Yellow Transparent, Drill, Oil Black Paint, Rolling, Zinc Plated, Anti-rust Paint, Shot Blasting, Sand Blasting, Heat Treatment, Punch |

| Other Testing | Carbon Equivalent, Hardness, Grain Size, A for annealed, NT for Normalized and Tempered, N for normalized, NACE MR0175, Macro, SSC, or QT for Quenched and Tempered, Ultrasounic Test, HIC, Sour Service, Charpy Impact Test etc. |