STAINLESS STEEL 316-316L

316/1.4401/UNS S31600

316L/1.4404/UNS S31603

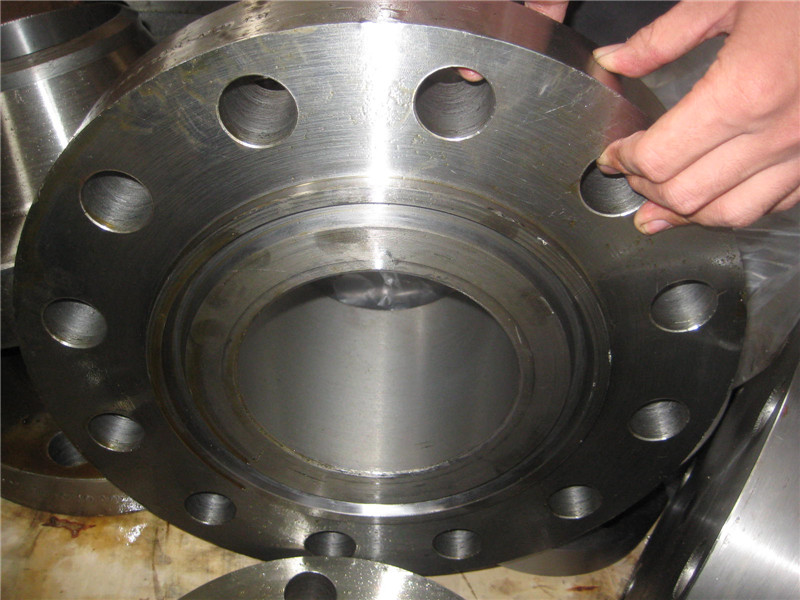

ASTM A182 F316L is a type of stainless steel flange that is widely used in various industries such as petrochemical, chemical, and food processing plants. These flanges are resistant to corrosion and high temperatures, making them suitable for use in harsh environments. This material is a low-carbon version of F316, which contains molybdenum and nickel, giving it improved resistance to corrosion. The flange is available in various sizes and types, including weld neck(WN), slip-on(SO), blind, and socket weld(SW), etc.

Chemical Composition

|

|

Ni

|

Cr

|

Mo

|

Mn

|

Si

|

C

|

S

|

P

|

N

|

Fe

|

|

MIN

|

10.0

|

16.0

|

2.0

|

-

|

-

|

-

|

-

|

-

|

-

|

|

|

MAX

|

14.0

|

18.0

|

3.0

|

2.0

|

0.75

|

0.03

|

0.03

|

0.045

|

0.1

|

Balance

|

Physical Properties

|

|

70

|

212

|

932

|

1832

|

|

Coefficient* of Thermal Expansion, in/in°F x 10-6

|

-

|

9.2

|

10.1

|

10.8

|

|

Thermal Conductivity

Btu • ft/ft2 • hr • °F

|

7.8

|

-

|

-

|

-

|

|

Modulus of Elasticity Dynamic, psi x 106

|

29

|

-

|

-

|

-

|

Density: 0.285 lb/inch3

Poisson's Ratio: 0.3

Electrical Resistivity: 445 Ohm-circ mil/ft

Mechanical Properties

Representative Tensile Properties

|

Ultimate Tensile Strength, ksi

|

75

|

|

0.2% Yield Strength, ksi

|

30

|

|

Elongation, %

|

40

|

|

Hardness MAX, Brinell

|

217

|

Typical Tensile and Impact Properties

|

Temperature, °F

|

70

|

200

|

400

|

600

|

800

|

1000

|

1200

|

1400

|

|

Ultimate Tensile Strength, ksi

|

82.4

|

75.6

|

71.1

|

71.1

|

71.1

|

68.4

|

50.7

|

30.7

|

|

0.2 % Yield Strength, ksi

|

42.4

|

-

|

-

|

-

|

26.5

|

23.4

|

22.6

|

-

|

|

Charpy Impact V-notch, ft-lbs

|

65 - 100

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

Stainless steel 304 is a common material used for flanges, but F316L offers several advantages over it. F316L is more corrosion-resistant and has better heat resistance, making it a more practical choice for a wider range of applications. In addition, F316L has lower carbon content than F304, resulting in improved weldability and reduced sensitization to intergranular corrosion.

When it comes to applications that require high strength, corrosion resistance, and durability, F316L stainless steel flanges are the way to go. These flanges are essential components in a fluid handling system and are widely used in oil and gas refineries, power generation facilities, chemical plants, and pharmaceutical industries.

(1)_300x225.jpg)