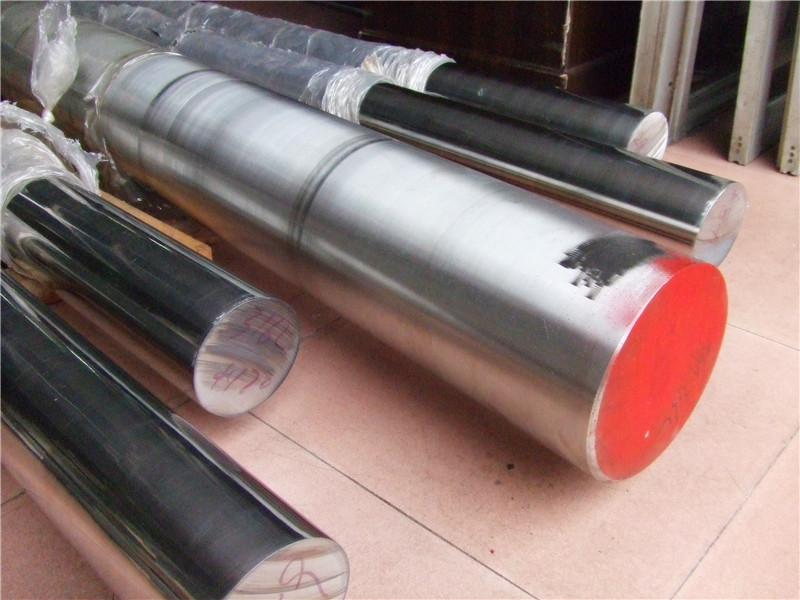

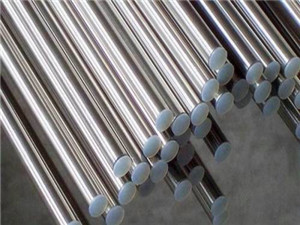

China ASTM B637 Inconel 718 Alloy 718 UNS N07718 DIN 2.4668 Haynes 718 Steel Round Bar Rod

HT PIPE provide Inconel 718 Nickel alloy round bar, Alloy 718 Bar supplier in China. 2.4668 round bar, UNS N07718 rod, Alloy 718 flat Bar, Inconel 718 hollow bar, Inconel 718 Nickel alloy round bar supplier, exporter

1. INCONEL 718 ROUND BAR

Inconel 718 is an alloy formulated of nickel and chromium for the operations that require high temperature resistance and corrosion. The non-magnetic alloy has distinguished mechanical properties that exhibits the unification of high strength and weldability with the support of wide range of temperature. The large proportion of nickel equips the alloy against corrosion from many organic and inorganic compounds. The alloy delivers exquisite resistance to stress corrosion, chloride ion and to alkaline solutions. The alloy acquires hardness and strength particularly by cold works.

2.Because of its unique array of properties, alloy 718 is popular with a number of different critical industries and applications including:

-

Gas turbine components

-

Cryogenic storage tanks

-

Jet engines

-

Liquid fueled rocket motors and components

-

Fasteners and instrumentation parts

-

Nuclear fuel element spacers

-

Hot extrusion tooling

-

Down hole shafting and strength bolting

3.Nickel Alloy 718 and Inconel 7l8 consists of over 50% nickel and of a number of different elements:

-

Ni 52.5%

-

Fe 18.5%

-

Cr 19%

-

Cb+Ta 5.13%

-

Mo 3.05%

-

Ti 0.9%

-

Al .5%

-

Co 1% max

4.Performance of Nickel Alloy 718

Alloy 718 is classified as "age-hardenable," meaning that its resistance properties increase over time—especially with prolonged exposure to cold temperatures. Numerous AMS and NACE specification processes can be deployed to customize its application-specific performance characteristics.

Additionally, heat treatments can be used to soften the alloy prior to welding, forming or machining. Its machinability rating is 12% of B-1112, and it has typical stock removal rates of 20 surface feet per minute with high-velocity tools and 80 surface feet per minute with carbide tools.

.jpg)

.jpg)