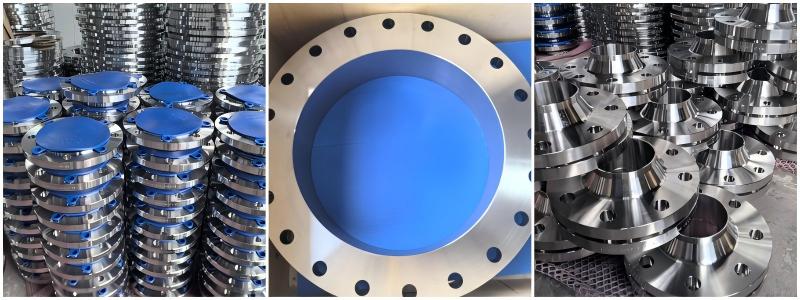

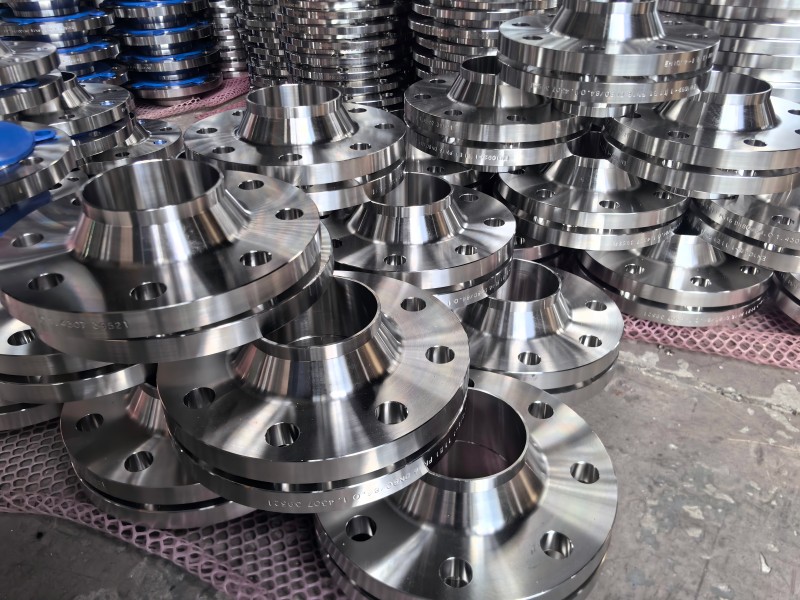

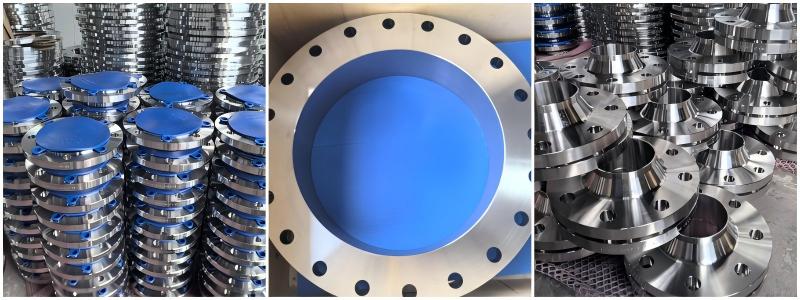

HT PIPE supplies the different types of Stainless steel Flanges according to ASTM, ASME, EN, ISO, DIN and JIS

Stainless steel Flanges ASTM materials:

ASTM A182: Covers forged stainless steel flanges

ASTM A240: Specifies stainless steel plates for flanges

Grades: F304, 304L, 304H, 316, 316L, 310S, 347, 347H, 317, 317L, 904L, 254SMO, 2205, 2507 etc

Stainless steel Flanges Types:

Types: WN Flange, LWN Flange, SO Flange, SW Flange, Blind Flange, Plate Flange, Threaded Flange, Lap Joint Flange, Orifice Flange, Spectacle blind flange.

Special products: rings, forged parts, disc, shaft sleeve

Sealing Surface: RF FF RTJ TF GF LF LM

The main Stainless steel Flanges Specifications:

Stainless steel WN Flanges Specifications:

Standard: ASME B16.5, ASME B16.47A, ASME B16.47B, EN, BS

Class: 150#-2500#, PN2.5-PN100

Size: 1/2”-48”, DN10-DN4000

Stainless steel SO Flanges Specifications:

Standard: ASME B16.5, DIN2543, DIN 2544, DIN 2545

Class: 150#-2500#, PN16, PN25, PN40

Size: 1/2”-24”, DN10-DN1000

Stainless steel SW Flanges Specifications:

Standard: ASME B16.5

Class: 150#-1500#

Size: 1/2"-3"(Except 1500# 1/2"-2 1/2")

Stainless steel Threaded Flanges Specifications:

Standard: ASME B16.5, DIN2565, DIN2567, DIN2568, DIN2569, JIS B2220

Class: 150#-900#, 1500#, 2500#, PN6, PN16, PN25, PN40, PN64, PN100

Size: 1/2"-24", DN6-DN200

Stainless steel Blind Flanges Specifications:

Standard: ASME B16.5, ASME B16.47A, ASME B16.47B, DIN2527, EN

Class: 75#-2500#, PN2.5-PN100

Size: 1/2"-48", DN10-DN4000

More Flanges standard and siza info please check the ANSI FLnge Standard: https://www.htpipe.com/d/files/flanges-standard/ansi-flange-standard-ht-pipe.pdf

Stainless steel Flanges Chemical Composition:

| Grade |

UNS |

C≤ |

Mn |

P≤ |

S≤ |

Si≤ |

Cr |

Mo |

Ni |

| 304 |

S30400 |

0.07 |

2 |

0.045 |

0.03 |

0.75 |

17.5-19.5 |

- |

8.0-10.5 |

| 304L |

S30403 |

0.03 |

2 |

0.045 |

0.03 |

0.75 |

17.5-19.5 |

- |

8.0-12.0 |

| 304H |

S30409 |

0.04-0.10 |

2 |

0.045 |

0.03 |

0.75 |

18.0-20.0 |

|

8.0-10.5 |

| 316 |

S31600 |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

16.0-18.0 |

2.00-3.00 |

10.0-14.0 |

| 316L |

S31603 |

0.035 |

2 |

0.045 |

0.03 |

0.75 |

16.0-18.0 |

2.00-3.00 |

10.0-14.0 |

| 316Ti |

S31635 |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

16.0-18.0 |

2.00-3.00 |

10.0-14.0 |

| 317 |

S31700 |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

18.0-20.0 |

3.0-4.0 |

11.0-15.0 |

| 317L |

S31703 |

0.03 |

2 |

0.045 |

0.03 |

0.75 |

18.0-20.0 |

3.0-4.0 |

11.0-15.0 |

| 321 |

S32100 |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

17.0-19.0 |

- |

9.0-12.0 |

| 310S |

S31008 |

0.08 |

2 |

0.045 |

0.03 |

1.5 |

24.0-26.0 |

- |

19.0-22.0 |

| 347 |

S34700 |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

17.0-19.0 |

- |

9.0-13.0 |

| 254SMO |

S31254 |

0.02 |

1 |

0.03 |

0.01 |

0.8 |

19.5-20.5 |

6.0-6.5 |

17.5-18.5 |

| AL-6XN |

N08367 |

0.03 |

2 |

0.04 |

0.03 |

1 |

20.0-22.0 |

6.0-7.0 |

23.5-25.5 |

| F904L |

N08904 |

0.02 |

2 |

0.045 |

0.035 |

1 |

19.0-23.0 |

4.0-5.0 |

23.0-28.0 |

| 2205 |

S31803 |

0.03 |

2.00 |

0.03 |

0.02 |

1.00 |

21.0–23.0 |

2.5–3.5 |

4.5–6.5 |

| 2205 |

S32205 |

0.03 |

2.00 |

0.03 |

0.02 |

1.00 |

22.0–23.0 |

3.0–3.5 |

4.5–6.5 |

| 2507 |

S32750 |

0.03 |

1.20 |

0.035 |

0.02 |

0.80 |

24.0-26.0 |

3.0-5.0 |

6.0-8.0 |

Stainless steel Flanges Mechanical Properties:

| Mechanical properties |

Tensile, min, ksi[MPa] |

Yield, min, ksi[MPa] |

Elongation, %(min) |

| 304 |

75【515】 |

30【205】 |

40 |

| 304L |

70【485】 |

25【170】 |

40 |

| 304H |

75【515】 |

30【205】 |

40 |

| 316 |

75【515】 |

30【205】 |

40 |

| 316L |

70【485】 |

25【170】 |

40 |

| 316Ti |

75【515】 |

30【205】 |

40 |

| 317 |

75【515】 |

30【205】 |

35 |

| 317L |

75【515】 |

30【205】 |

40 |

| 321/H |

75【515】 |

30【205】 |

40 |

| 310S |

75【515】 |

30【205】 |

40 |

| 347/H |

75【515】 |

30【205】 |

40 |

| S31254 |

95 [655] |

44 [305] |

35 |

| N08367 |

95 [655] |

45 [310] |

30 |

| N08904 |

71【490】 |

31【220】 |

35 |

| S31803 |

90 [620] |

65 [450] |

25 |

| S32205 |

95 [655] |

65 [450] |

25 |

| S32750 |

116 [800] |

80 [550] |

15 |

Stainless steel Flanges Production Methods

Forging, Casting, Machining

Flanges cut from stainless steel bars or plates for custom sizes or low-volume production.

Heat Treatment:

Solution Annealing: Heated to 1,050–1,100°C and quenched to restore corrosion resistance.

Stress Relieving

Surface Treatment:

Pickling/Passivation: Removes iron contaminants and enhances the passive oxide layer.

Electropolishing: Improves hygiene and aesthetics (common in food/pharma)

Stainless steel Flanges Testing and Quality Assurance

PMI

Size

Non-Destructive Testing (NDT)

Radiographic (RT) and Ultrasonic (UT) Testing

Dye Penetrant (PT) and Magnetic Particle (MT) Testing: Identify surface cracks.

Hydrostatic Testing

Mechanical Testing: Tensile, impact, and hardness tests

Corrosion Testing:

ASTM G48: Evaluates pitting and crevice corrosion resistance.

Intergranular Corrosion (IGC) Test: For sensitized austenitic grades.

Stainless steel Flanges Applications

Oil & Gas: Offshore platforms, pipelines (duplex grades for chloride-rich environments).

Chemical/Petrochemical: Handling acids, alkalis, and corrosive media (super austenitic grades).

Food & Beverage: electro polished surfaces (316L).

Pharmaceuticl: Sterile systems requiring cleanability and corrosion resistance.

Power Generation: High-temperature steam lines (321/347).

Marine: Seawater cooling systems (316/2205).

(1)_300x225.jpg)