ASTM B673 is the Standard Specification for UNS N08925, UNS N08354, and UNS N08926 Welded Pipe for general corrosion applications. ASTM B673 UNS N08926 welded pipe shall be made from flat-rolled alloy by an automatic welding process with no addition of filler metal.

The recommended heat treatment shall consist of heating to a temperature of 2010 to 2100°F (1100 to 1150°C) for UNS N08926, followed by quenching in water or rapid cooling by other means.

UNS N08926 welded pipe shall be furnished with oxide removed. When solution treatment is performed in a protective atmosphere, descaling is not necessary.

ASTM B673 UNS N08926 welded steel pipe Specification

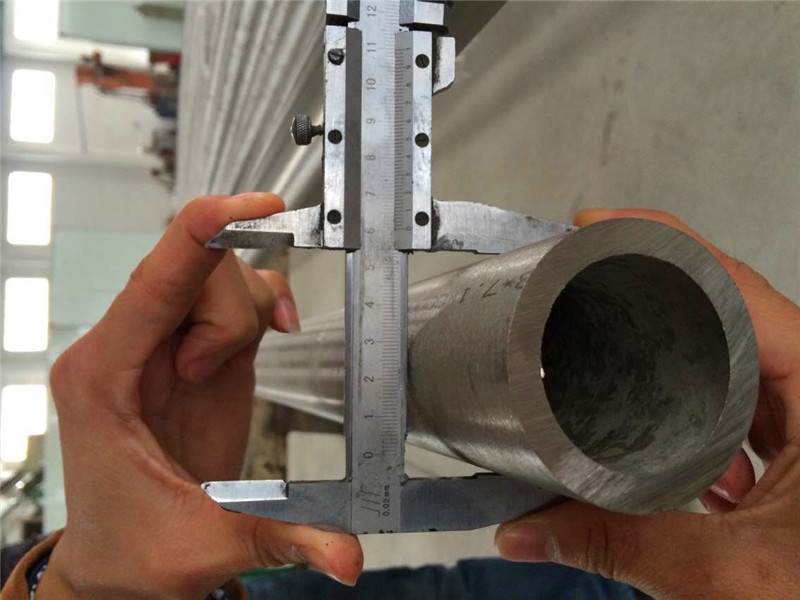

Outside Diameter: 1/8"~30"

Wall Thickness: SCH5S, SCH10S, SCH20, SCH30, SCH40S, STD, SCH80, XS, SCH60, SCH80S, SCH160S

Manufacture Process: Hot rolling /Hot work ,Cold rolling

Manufacturing Standards: ASME B36.19

ASTM B673 UNS N08926 Chemical Requirements

Manganese, max 2.00

Phosphorus, max 0.03

Sulfur, max: 0.01

Silicon, max: 0.5

Nickel: 24.00 to 26.00

Chromium: 19.00 to 21.00

Molybdenum: 6.0 to 7.0

Copper: 0.5 to 1.5

Nitrogen: 0.15 to 0.25

Iron: balance

| ASTM B673 /ASME SB673 |

Specification for UNS N08925, UNS N08354, and UNS N08926 Welded Pipe |

| Material Grade |

UNS N08925 |

UNS N08354 |

UNS N08926 |

|

|

| Size |

1/2''~48'' |

| Thickness |

SCH5~SCHXXS |

| End |

Beveled End,Plain End |

| Length |

As per your requirement. |

| Packing |

Export Standard packing or as per your requirements. |