Stainless steel includes Ferrite, Austenite, Austenite-ferrite Duplex Stainless steel, and Martensitic stainless steel; Industrial Stainless steel Pipe is a metal pipe used in various industrial fields. It can be divided into many types according to different materials; Martensitic Stainless steel has high strength, but its plasticity and weldability are poor.

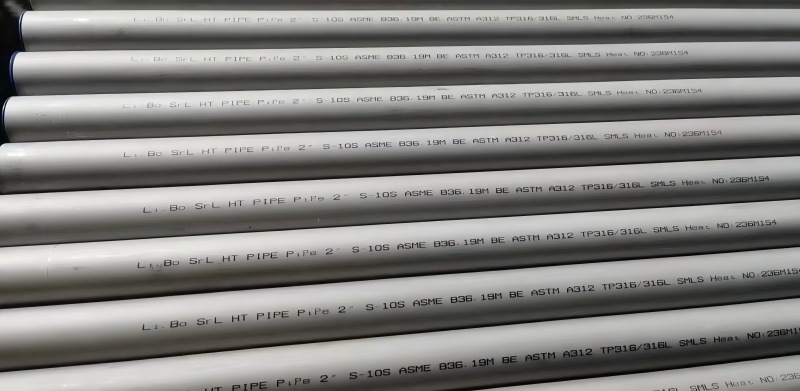

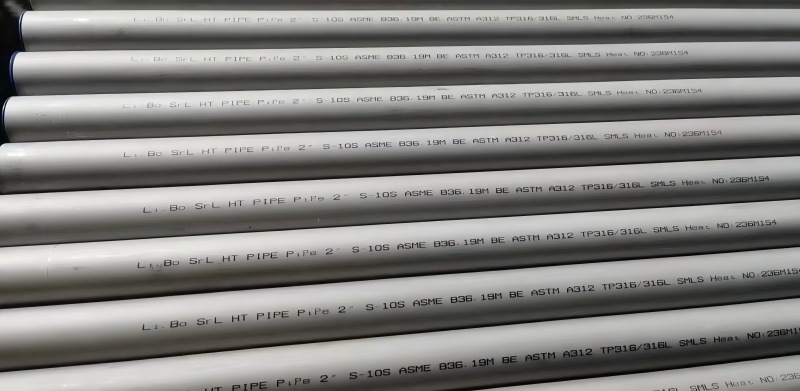

As a company specializing in the supply of Pipeline, HT PIPE supplies Industrial Stainless steel Pipes such as 304 stainless steel industrial pipe, 304L stainless steel industrial pipe, 316 stainless steel industrial pipe, 316L stainless steel industrial pipe, 317/L stainless steel pipe, 310 stainless steel industrial pipe, 321 stainless steel pipe, 904L stainless steel pipe and other Ferrite Stainless steel Pipes, Austenitic Stainless steel Pipes, and Austenitic-ferrite Duplex Stainless steel Pipes.

Industrial Stainless steel Pipes Standard:

ASTM A312: Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A213: Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A269: Stainless Steel Tubing for General Service

ASTM A790 : Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A789: Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

Common materials and grades:

Austenitic stainless steel (such as 304, 316) has excellent comprehensive performance and is the most widely used: it contains more than 18% chromium, about 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. It has good comprehensive performance and can resist corrosion from a variety of media

| Grade |

Characteristics |

Application |

| 304/304L |

Low carbon version, excellent resistance to grain boundary corrosion; wide temperature resistance range (-196°C~700°C) |

Food equipment, chemical piping, building structures |

| 316/316L |

Molybdenum added, excellent resistance to chloride ion corrosion |

Marine engineering, chemical industry, seawater treatment |

| 310S |

High temperature resistance up to 1150°C, good oxidation resistance |

Boiler liner, automobile exhaust pipe, heat exchanger |

| 321 |

Containing titanium elements, resistance to intergranular corrosion, high temperature resistant |

Aviation, aerospace high temperature parts |

More Stainless steel Pipes info, pls check: https://www.htpipe.com/products/steel-pipe-tube/stainless-steel-pipe-tube.html

Industrial Pipes Applications

Petrochemical

Requirements: High pressure and corrosion resistant seamless pipes (e.g. 316L, 321).

Scenario: material transportation pipe, heat exchanger, high pressure furnace pipe (wall thickness 6-50mm).

Energy & Power

Boiler and heat exchanger tubes need to resist high temperature and high pressure (such as 310S, 316L), the implementation of the standard ASTM A213.

Food & Pharmaceutical

Sanitary tubes: inner wall polished to mirror surface (Ra≤0.8μm) to prevent bacteria retention, made of 304L/316L.

Applications: dairy piping, pharmaceutical equipment, water purification systems.

Automotive & Transportation

Ferritic stainless steel welded pipe for exhaust system (e.g. 409L), accounting for more than 50% of the stainless steel used in automobiles.

Construction and environmental protection

Thin wall stainless steel pipe (wall thickness 0.6-1.2mm): replace galvanized steel pipe, become the first choice for drinking water system (such as 304), with environmental protection, long life advantage.

Manufacturing process of stainless steel industrial pipes

Seamless pipe: billet piercing→hot rolling/cold rolling→sizing→testing (hydraulic test, ray detection).

Welded pipe: coil → welding → weld treatment → solution annealing (industrial pipe needs online annealing to safeguard performance).

Quality Testing

Pressure testing, radiographic inspection, flare/flatten test to ensure pressure resistance and sealing.