HASTELLOY C276, UNS N10276 is considered the most versatile corrosion resistant nickel alloy available. Alloy C-276 also has excellent resistance to pitting, stress-corrosion cracking, especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosive environments.

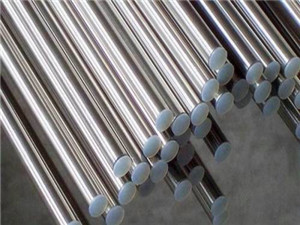

HT PIPE provide Hastelloy C276 Nickel alloy round bar, Alloy C276 Bar supplier in China. 2.4819 round bar, Alloy C276 rod, UNS N10276 rod, Alloy C276 flat Bar, Hastelloy C276 hollow bar, Hastelloy C276 Nickel alloy round bar supplier, exporter.

What are the characteristics of Hastelloy C276?

- Excellent corrosion resistance in reducing environments

- Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

- High nickel and molybdenum contents providing good corrosion resistance in reducing environments

- Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

- Resistance to localized corrosion such as pitting and stress-corrosion cracking

- One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Hastelloy C276 Nickel alloy round bar Chemical Composition, %

| Ni |

Mo |

Cr |

Fe |

W |

Co |

Mn |

C |

V |

P |

S |

Si |

| Remainder |

15.0-17.0 |

14.5-16.5 |

4.0-7.0 |

3.0-4.5 |

2.5 max |

1.0 max |

.01 max |

.35 max |

.04 max |

.03 max |

.08 max |

ASTM Specifications

| Pipe Smls |

Pipe Welded |

Tube Smls |

Tube Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

Wire |

| B622 |

B619 |

B622 |

B626 |

B575 |

B574 |

B564 |

B366 |

|

Hastelloy C276 Physical properties

Melting point: 1325-1370 ℃

Density: 8.90 g/cm3

Alloy C276 Bar Mechanical Properties

| Mechanical properties |

Tensile, min, ksi[MPa] |

Yield, min, ksi[MPa] |

Elongation, %(min) |

| Hastelloy C276 |

100[690] |

41[283] |

40 |

Typical Room Temperature Tensile Properties of Annealed Material

| Product Form |

Tensile (ksi) |

.2% Yield (ksi) |

Elongation % |

| Bar |

110.0 |

52.6 |

62 |

| Plate |

107.4 |

50.3 |

67 |

| Sheet |

115.5 |

54.6 |

60 |

| Tube & Pipe |

105.4 |

45.4 |

70 |

.jpg)

.jpg)